- Minimised energy consumption owing to effective vacuum exhausters not requiring any seal water.

- Electrical power savings by frequency controlled speed regulation ensures a minimised power consumption concerning fabric width, porosity

- also, line speed.

- They are easy operated by Computerised control system with adapted software for the automatic process.

- Digital vacuum regulation with PID-function ensures an even extraction of the fabric.

- High-efficiency separators with no blocking filter

- of the air stream minimising pressure fall.

- They are equipped with level controlled drain-pump automatics, saving both chemicals and compressed air.

Adapting textile production to necessary environmental requirements is one of the most critical and urgent challenges for today’s textile processing mills.

OptiVac extraction systems offer the textile finishing significant benefits and savings and simultaneously dramatically reduced environ impact!

During 30 years, our customers have successfully run both sustainable and profitable textile applications using

OptiVac in 36 countries worldwide. Increased drying capacity, using less energy consumption.

Although many advanced squeeze rollers exist today, the fact remains their dewatering effect cannot be improved any further. High line speed causes aquaplaning. Viscous liquids are squeezed back into the fibre structure or adhered to the fabric and squeezing bowls.

NEXT

manufacturer of vacuum extraction systems for the modern textile industry

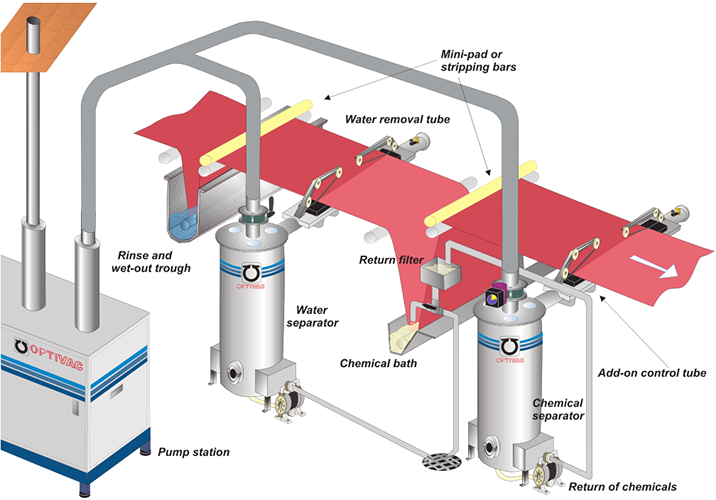

The OptiVac High Tech Extraction Systems are designed to enable a complete utilisation of all the benefits provided by the vacuum technique.

Investing in an OptiVac means saving energy, water and chemicals i.e. protecting the environment.

Improved quality and higher production capacity will result in lower costs of capital and wages.

They create new possibilities and open new ways for a much more rational textile wet processing.

The OptiVac systems are of highest workmanship and designed to meet all the demands of the machine and textile technology, which are by far the determining factors for a successful application of the vacuum technique.

The OptiVac High Tech Extraction Systems belong to every professional textile finishing plant!

The OPTIVAC AB serving the textile finishing industry worldwide since 1989.

As the 5th generation of textile finishers the founder Björn Grauers decided to design the

“OptiVac Vacuum Extracting System”, that both meet the textile technical and mechanical requirements as well, thereby ensuring an optimal finishing result.

After serving the textile finishing industry in three decades, we are aware about the customers different fabrics i.e. special needs.

At our location in Sweden, the company produces vacuum extraction machinery for wet finishing processes, and dry lint removal of textiles and carpets.

Implementation of the OptiVac Extracting System’s in the textile wet processing is very profitable because the systems, not only reduces emissions of carbon dioxide, but the production costs are also significantly reduced. Also dramatically improved quality and handle of the fabric achieved at the same time as the production speed can be considerably increased. Often the maximal stenter speed is the speed limit!

By using the OptiVac extracting system the saving of hot process water is an additional and important benefit, in our world, where the lack of water is a serious problem.

Improve

Fabric Quality

Extraction enables controlled wet-in-wet finishing and a complete and even distribution of dyes and chemicals inside the fibre structure.

Efficient removal of removes excess chemicals, preventing the ”window pane” effect.

The low and even finishing content prevents migration in the following drying process.

Scrutinising fabrics dyed on an OptiVac shows how very even the dyes are

distributed both face and reverse side throughout the whole fibre structure.

The unique design of OptiVac extraction slots, ensures no drops nor splashes occur outside the vacuum tube.

Low friction heat-resistant (up to the boiling point) polymer slots ensure minimal impact to fabric fibre structure and are suitable for both delicate and heavy fabrics.

Coat or Print without Dust and Lint!

Dry extraction in front of a printing or coating process is also very advantageous.

Dust, lint and attaching threads are instantly removed, preventing from stains and rejects.

Compared to brushing units, which cause electrostatic charge to the fibres decreasing the cleaning efficiency, OptiVac dry extraction systems, achieve cleaner fabric at higher production speed.

An external filter collects dust and lint and prevents production stops caused by the need for cleaning.

Collected lint and dust is easily removed from the filter and put to deposit.

Picture taken at customer using OptiVac dry system. Considerable amounts of dust and lint are instantly removed and collected in the filter unit. Filter is easy accessable to be cleaned when required

Migration during drying

Final distribution after padder

(squeeze mangle)

Final distribution after extraction

Improved Chemical Finishing, Dyeing!

The OptiVac High Tech Systems are designed to perform a controlled “wet-in-wet” chemical finishing, sawing a pre-drying. Dye liquids, or chemical finishing, are completely evenly distributed inside the fibre structure, not only on the fabric's surface. Because of the very low moisture quotient, migration is prevented during the following drying process.

The OptiVac extraction systems ensure absolute even residual moisture, “side-centre-side” and “reverse side to face”. The explanation is simple.

When the fabric passes the slot opening, a completely even air pressure is created along the total fabric width, regardless how wide the fabric is.

When fabrics, dyed on an OptiVac Dyeing System, are scrutinised, it is easy to see how even the colour is distributed on the face as well as on the reverse side, and throughout the fibre structure of the fabric.

The impregnated bath stays inside the fibre bundles, not between the yarns, this prevents migration of the bath to the surface during the drying process.

Do you want to know more what vacuum technology can do for your textile production? Increase production, reduce energy. It is right for your company and our environment. Contact us, and we will tell you more.

OptiVac AB

Trastvägen 27

44 835 Floda

Sweden